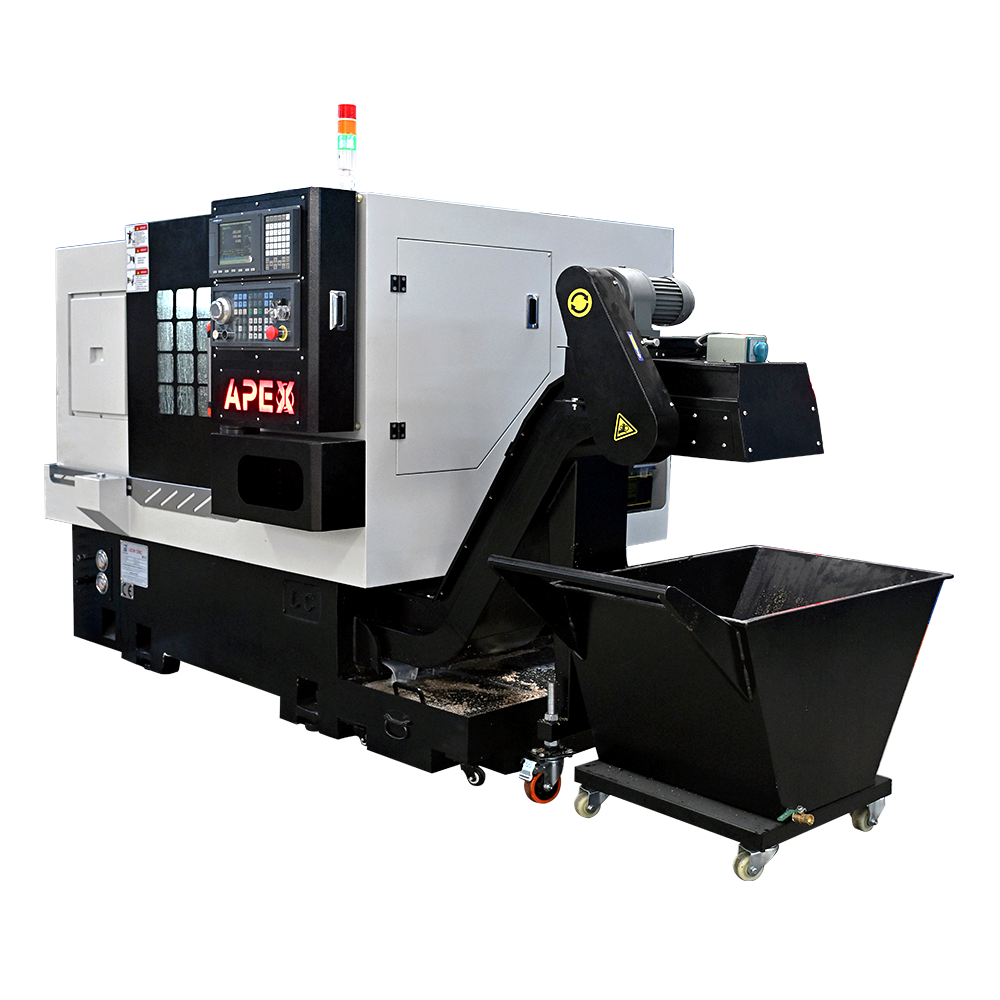

APEX 42-C

. HIGH SENSITIVITY . HIGH EFFICIENCY . HIGH QUANTITY

CNC automat lathes, with its high precision operation and easy programmable feature, increases your productivity and allows you to reach high quantities. With its strong live tool, it allows you to process from diameter and forehead.

If desired, you can also perform angled operations by adjusting the diameter of the live tool.

| Control Unit | SYNTEC 22TA |

| Spindle Norm | A2-5 (173E) |

| Spindle Bore Diameter | Ø45 mm |

| Max. Turning Diameter | Ø168 mm |

| Max. Turning Length | 280 mm |

| Spindle Motor Power | 7.5 kW |

| Spindle Cycle | 5000 rpm |

| Bar Processing Capacity | Ø42 mm |

| Inclined Counter Angle | 35° |

| Positioning Accuracy | 0.005 mm |

| Turning Coulter Size | 20×20 mm |

| Hole Catenary Size | Ø20 mm |

| X / Z Axis Serial Movement Speed | 28 m/min. |

| X Axis Movement Distance | 450 mm |

| Z axis Movement Distance | 300 mm |

| X / Z Axis Motor Power | 1.8 kW |

| Live Tool Motor Power | 2.5 kW |

| Hydraulic Motor Power | 1.5 kW |

| Hydraulic Pressure | 3 Mpz |

| Ball Screw | 32mm |

| Linear Slide | 30mm |

| Dimensions (LxWxH) | 1850x1450x1750 mm |

| Weight | 2800 kg |

| OPTIONAL | CHIP CONVEYOR / PART CATCHER |

What Are We Doing?

CNC Machines and Machines

Polyurethane cast bearing and antivibration system with easy diameter adjustment With the servo motor drive system, the material rotates at high speeds without vibration.

Servo motor driving system, PLC and special software for precise length driving realisation, material escape and dimensional errors are prevented.

Polyurethane cast bearing and V-type antivibration system vibration-free rotation is ensured at high speeds.

Four different diameter channels are combined with a single monoblock bearing system. In this way, diameter changes can be made in a short time.

There is no risk of vibration as the entire material rotates in the spindle. High speeds can be reached especially for hexagonal, profile and large diameter materials.

Thanks to the servo motor, material positioning is precise. It does not hit the turret and the rest.